When installing thermowells in a pipeline, a user must first answer several questions regarding their location, quantity, stem length, distance from each another, and effects on the process media.

Thermowells are highly effective devices for protecting temperature sensors, such as resistance thermometers (RTDs), from process media in a pipeline. They are usually inserted perpendicular to the flow, using a flange connection. However, there’s an art to thermowell placement and installation. Some of the most common questions I’ve received:

- What is the ideal insertion length for a thermowell?

- How far apart should thermowells be from each other?

- Where in relation to an elbow should the thermowell be installed?

Here are some answers about thermowell selection, placement, and installation.

1. Insertion length for a thermowell

The right length for a thermowell largely depends on the diameter of the pipe or tube. One rule of thumb is to insert a thermowell anywhere from one-third to two-thirds of the way into the fluid stream. Other guidelines recommend that the insertion length be 10 times the thermowell tip diameter or a minimum of 2 inches (50mm) into the process.

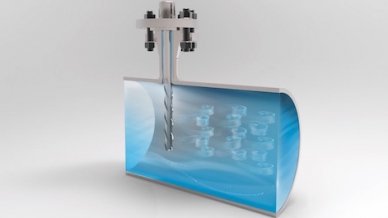

Helical strakes on a thermowell break up the vortices, rendering them too weak to cause mechanical fatigue.

The goal is to balance the potential for mechanical failure and the potential for sensing error. On the one hand, the longer the insertion length, the greater the chances that the thermowell will bend or suffer mechanical fatigue due to the process media’s velocity. On the other hand, the shorter the insertion length, the greater the chances that users will see unreliable results due to poorer heat transfer. In summary, there is not one perfect stem length for a thermowell, but a goal of balancing outcomes.

One way to reduce vibration and mechanical fatigue is to use a thermowell with a ScrutonWell® design, which has helical strakes to suppress vortex-induced vibrations. Rigorous endurance tests have prove the effectiveness of the ScrutonWell® Design as a vortex breaker.

2. Multiple thermowell installations

Most of the time, one thermowell with a temperature sensor is sufficient for a section of pipe. However, some processes call for multiple thermowells in an area. The key when installing several thermowells is to minimize their influence on one another while providing a consistent flow character in the process. There are two ways to do this:

Thermowells installed at offset angles

Offset angles – In this scenario, both thermowells are installed at the same location but at angled offsets from each other. By having them at the same location, they are not influenced upstream or downstream from an inline installation. They should be installed at a minimum angular offset to allow for easy installation and removal. Also, the thermowell tips should be far enough away from each other so as to not influence each other’s readings.

Thermowells installed inline

Inline – To ensure laminar flow in the process, the distance between thermowells can vary from 10 to 100 times the pipe diameter, a wide range indeed! Several factors go into how far apart inline thermowells should be placed, but a conservative estimate is 25 times the pipe size. For example, in a pipeline with a 4-inch (100mm) diameter, the distance between thermowell installations is about 8 feet (2.5m): 4″ x 25 = 100″ = 8.33′.

3. Elbow installations

The installation in an elbow allows the sensing area of the thermowell to be placed in the centerline of the pipe, ensuring an optimal location for measuring the process’s temperature. There are two different sites of thermowell installations in an elbow:

Thermowell installations in elbows: A. facing upstream, B. facing downstream

Facing upstream – The thermowell tip (temperature sensing area) is upstream of any influence, such as mixing or swirling, of the elbow. Many users prefer this elbow installation over “facing downstream” (see next bullet), although the bending moment calculations to ASME PTC 19.3 TW-2016 are outside the scope of this standard.

Facing downstream – The thermowell tip is downstream of the elbow, which means that it can be influenced by any mixing or swirling that the elbow causes. The advantage when performing thermowell wake frequency calculations is that facing downstream takes a conservative approach and assumes it is a perpendicular installation.

Other considerations for thermowell installation

Thermowell length, distance apart, and location are the main considerations when installing these protective fittings, but they are not the only ones. Users should also keep in mind these other factors:

- Pipe size – ranging from small (2″ to 4″) to large (> 60″)

- Process media – whether it’s gas or liquid

- Two-phase flow – such as gas and liquid, two different liquids, a liquid and solid particles, or a gas and solid particles

- Type of flow – steady or pulsating

- Distance from other measuring instruments or fittings

Many factors go into choosing the correct type, size, and location for a thermowell. For more information about which fitting is right your particular process and requirements, or where a thermowell should be installed in a pipeline, contact the temperature measurement specialists at WIKA USA.