With repeated exposure to high temperatures, a Type K thermocouple becomes less accurate. Aging is a phenomenon that results in higher-than-accurate temperature readings, while drift results in lower-than-accurate readings. While all Type K thermocouples experience …

high temperature

Case Study: Custom Pressure Sensor Withstands Aggressive Chlorinated Gas Environment

Patrick McGrath | PressureFor a leader in industrial flow equipment and services, one specific application was causing significant difficulties for their end user. The harsh environment – high-temperature chlorinated gas for fiber optic production – was causing half of their pressure …

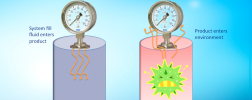

Diaphragm Seals Improve Reliability in Bioethanol Production

Ravi Jethra | Know-howIn bioethanol production processes, engineers must closely monitor pressure, temperature, level, and flow in order to ensure safe and efficient operations. Diaphragm seals in these applications do double duty: protect pressure measurement instruments from the medium, …